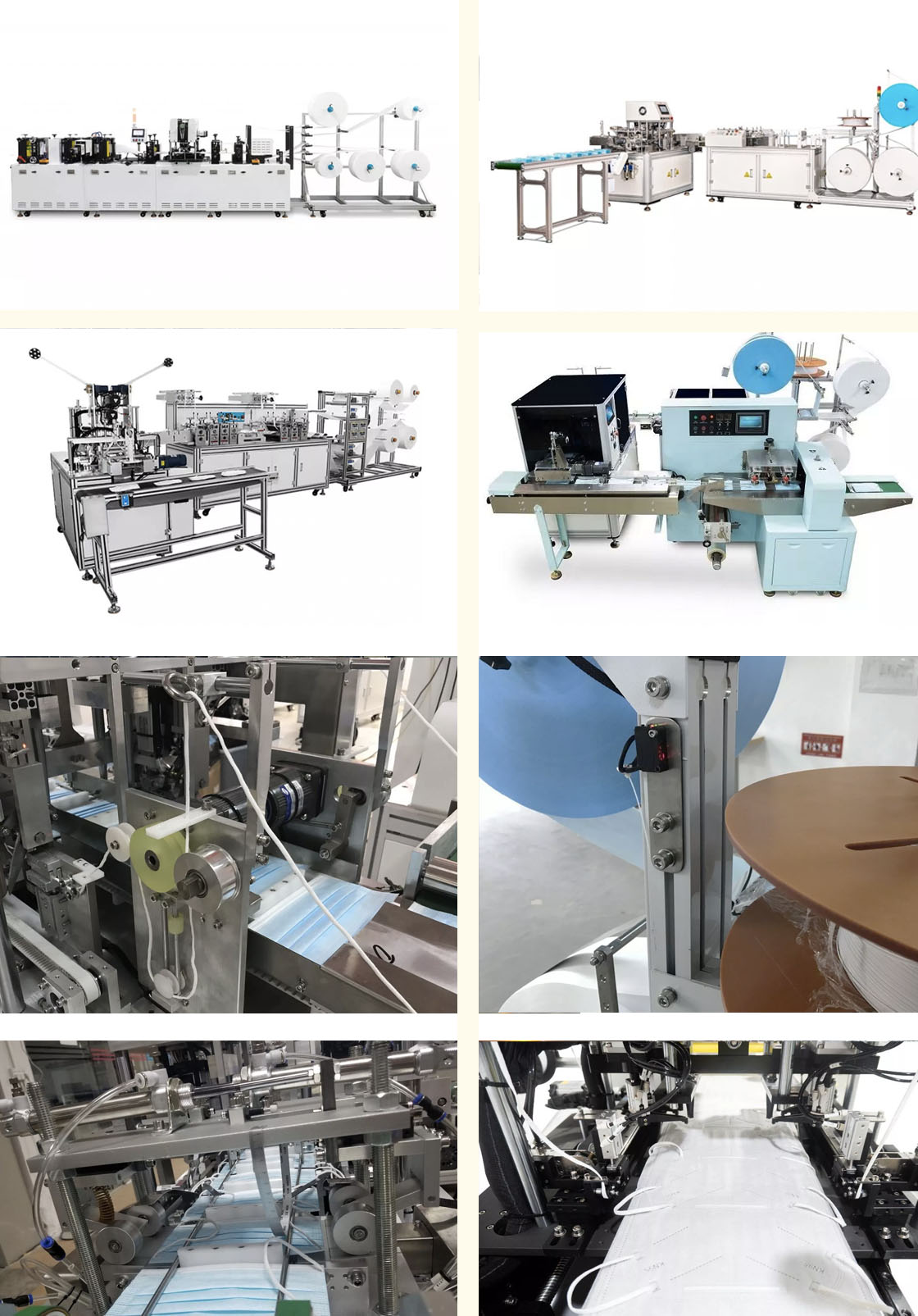

Aluminum Alloy Parts For Mask Making Machine

- Size: According to customers’ drawings

- Surface Treatment: Polish, Anodizing, sand blast, Powder Coating, PVDF Deep Processing, Precise Cutting, Drilling, Bending, Punching, CNC and Aluminum Profile Fabrication

- Origin: Foshan China

- Price Term: FOB ,CIF

- Delivery: Express, Air, Train,Ocean

- FOB Port: Guangzhou or Shenzhen, China

- Payment Term: T/T, L/C

- Grade: 6000 Series, 5052 or Custom

Shijun Hongmao Aluminum Co., Ltd. has been focusing on customized production of various special aluminum alloy profiles for 16 years. It is a customized production enterprise integrating aluminum profile extrusion and deep processing. It has more than ten precision aluminum extrusion lines, advanced belt double Traction extrusion equipment, high-precision CNC milling machine technology, vertical machining center and 10-meter long profile machining center, various aluminum profile processing machinery and equipment, has accumulated rich production expericence in special and difficult special-shaped aluminum profiles, according to customers. The use requirements, characteristics and functions of the products are optimized to design the product structure, and produce high-quality and qualified customised aluminum alloy profile products. Welcome to customization.

Specifications

ITEM: Aluminum Alloy Parts For Mask Making Machine

Product Material: National standard 6063, 6061 high-purity aluminum alloy

MOQ: According to customers' drawings or samples

Surface Treatment: Mill finish, polish, anodizing, sand blast, powder coating, wooden color, fluorocarbon coating, polished, brushed, etc.

Product structure design: Adopting European and American industrial aluminum profile design standards, light weight and high-end appearance

Product safety standards: Using high-strength aluminum alloy extruded profiles

Product life: The use of high-quality surface treatment and high-quality aluminum alloy materials can extend the service life

Packing Details:

Inside: Packed with protection film to protect the surface of each profile

Outside: Wrapped with hot shrink film and waterproof craft paper

Delivery Time: Die Tooling & Sample Testing: 7-15 days

Mass Production Completed: 15~25 days after samples are confirmed by the buyer

FOB Port: Guangzhou / Shenzhen / Foshan

Payment Term: T/T 30% for deposit and 70% for balance before shipping

Guarantee: Surface finish can be stable for 10~20 years for indoor usages

Characteristic Custom Produce: 16 years of experience in custom development and production of aluminum profiles, support custom development and production

Shipping : Ocean shipment, air shipment, land transportation and multi-transportation, etc.