What Is The Aluminum Profile Of The Industrial Assembly Line?

- By:sjhmalu

- Date:28-09-2022

How much do you know about assembly line aluminum profiles?

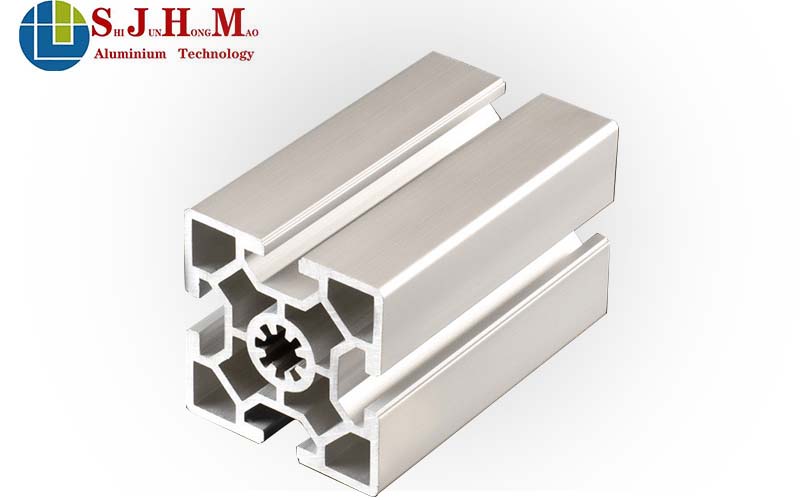

The assembly line aluminum profile is the so-called T-slot aluminum profile, which refers to the aluminum alloy profile used in the automatic machinery industry and production line. Material. The material is mostly 6063-t5, and the surface treatment is mostly anodized and frosted carbon coating. Anti-corrosion and wear-resistant, beautiful and durable, it is used in many production industries. It is often used to make various assembly line brackets, equipment aluminum profile racks, safety fence posts, large equipment frame structures, etc. What are the advantages of the T-slot aluminum profile? Let’s find out together.

·Good plasticity and simple processing method

The assembly line aluminum profile is an extruded section profile, which can be customized and processed according to the needs of different sections. And compared with traditional steel profiles, aluminum profiles are simple to process, requiring only simple design, cutting, punching, tapping, and installation with accessories, without welding, and eliminating the need for cutting, welding, sandblasting, and painting.

·Easy to disassemble and assemble, flexible and changeable, and good expandability.

The assembly line aluminum profiles are connected by matching accessories without welding and painting. And because of the use of accessories connection, the connection methods are various and flexible, and it is also convenient to expand and upgrade the product later. Traditional materials need to be welded, and welding is time-consuming and labor-intensive, and the cost is high. It is not easy to repair the welding connection points in the later stage, and it is not easy to upgrade the product in the later stage.

·The aluminum profiles have complete specifications and many surface treatment methods

The aluminum profile is a kind of aluminum alloy extruded profile, and there are hundreds of conventional specifications and models in the industry. It can also be designed and processed according to the needs of users. The surface treatment is diversified to meet the diverse needs of users and has a wide range of applications.

·Beautiful and durable, long use time

The surface treatment of the profiles is smooth and flat, there are also a variety of colors to choose from, and the overall appearance is elegant. Because the surface of the profile has been treated and covered with an oxide film, it can protect the profile from oxidation and corrosion, which is easier to oxidize than traditional materials. The aluminum profile is anti-corrosion and wear-resistant, not easy to rust and discolor, and can be used for a long time.

·Small error and high precision, suitable for high-precision equipment

The accessories used in the installation process of the assembly line aluminum profiles are not like traditional materials using welding, and the materials are easily deformed, so the assembly accuracy of the aluminum profiles is high. In addition, in the process of profile processing, the dimensional specifications and standards in the industry are referred to, and the tolerances are strict, which is suitable for the use of precision equipment with high precision requirements.

·Energy saving and environmental protection, can be recycled and reused multiple times, reducing enterprise costs Aluminum is an environmentally friendly material, with no need to paint and no pollution. It is connected by accessories, without welding, easy to disassemble, and the material can be recycled and reused. It saves time and effort and can be disassembled at any time, which can save labor and investment costs for enterprises.

In general, the T-slot aluminum profile is because of its simple processing method, many varieties, and complete specifications, light unit weight, good mechanical and physical properties, high connection strength, good bearing capacity, convenient disassembly and handling, beautiful and durable, energy saving and environmental protection, moderate price, Wide range of applications and other characteristics are loved by everyone.

What are the common processing methods of assembly line aluminum profiles?

The assembly line aluminum profile is the industrial aluminum profile used on the production line in the workshop. It is widely used in production, assembly, and testing in electronics, food, and other industries. The aluminum profile of the assembly line is extruded from the original aluminum ingot, which has a good bearing capacity and high connection strength. It can be processed by CNC and can be customized for the automatic production line. So what are the commonly used processing methods?

Cutting: The length of one aluminum profile of the assembly line is 6 meters, which can be cut by size and angle according to needs. During the cutting process, it is necessary to pay attention to the control of precision and to ensure that the section is smooth and free of burrs. The proportion of cutting in processing is very large, so it is necessary to use good CNC equipment and tools to reduce cutting errors.

Punching: Not every assembly line equipment will use punching. Punching is generally used for the installation of accessories, and the accessories can be placed in the profile, which is beautiful and strong. The types of punching holes are: through holes, countersunk holes, blind holes, and mounting holes. Different holes have different functions. The position accuracy and depth of the hole should be strict to the requirements of the design drawings.

Tapping: including end face tapping and drilling tapping, using suitable lubricant to achieve tap life and precise depth control. Tapping is generally carried out in the middle hole of the end face of the profile, and it is necessary to pay attention to tapping within the size range of the hole.

Finishing machining: including hole milling, slot milling, face milling, end milling, bending, etc., requires professional CNC equipment for precise machining.

Assembly: Assembly can be done at our place or the customer’s place. If the amount of work is relatively large and the distance is relatively long, it is generally recommended to use on-site installation. We provide installation guidance and on-site installation services. Professional tools, such as Allen wrench, rubber mallet, etc., are required for assembly, to reduce the damage to accessories.

What are the application areas of industrial aluminum profiles in the field of industrial assembly lines?

Looking around, as long as there is industrial production, you will see industrial aluminum profiles, such as automobile assembly workshops, household appliance factories, robotics, automation, food production workshops, chemical raw material production lines, etc. When it comes to assembly line equipment, the application of industrial aluminum profiles in the field of assembly lines is also very important.

The assembly line is also called the assembly line. Its frame is composed of industrial aluminum profiles, and then it is divided into many types according to different functions. The most commonly used is the belt line, the chain plate line, and the roller assembly line. It is a combination of man and machine. In the industrial production mode, it can be transported to a specified itinerary, and can also complete many different tasks simultaneously. The transport volume is quite large, and the efficiency is much higher than that of manual production. Therefore, assembly line equipment is inseparable from industrial production.

The most commonly seen is the assembly line equipment of the electronics factory, which is generally a belt line assembly line, because the products of the electronics factory are usually relatively small and delicate, and the belt line is installed on the industrial aluminum profile frame to withstand those weights. Some assembly lines are also equipped with aluminum workbenches to place some tools and materials. Some workbenches need anti-static, which are also made of industrial aluminum profiles, which can play an anti-static role and ensure the safety of production.

The corresponding material turnover car should be equipped next to the assembly line. The things produced by each assembly line are different, and the materials placed are also different. Putting the materials on the aluminum profile turnover car in advance is very important for improving production efficiency. necessary steps. The products produced cannot all be stacked on the site but must be placed in designated places separately because many semi-finished products need to be placed for a certain period before entering the next process, which requires the use of industrial aluminum profile racks to place them.

According to different needs, industrial aluminum profile racks have general storage racks and aluminum profile wire bar racks, which have a certain bearing capacity. The aluminum profiles are equipped with corresponding bolts, nuts, angle pieces, and other accessories, and then installed with casters, so that they can move back and forth. , It is very simple and convenient to assemble, and it can be used continuously after disassembly. It will not be wasted at all. The products produced on the assembly line are placed on the aluminum profile shelf so that the products can enter the next production link.

If it is a car factory, many parts and components must be completed by assembly lines during production. Because the output of automobiles is large and the efficiency of manual production is low, assembly lines are essential. Robots are used in both the welding workshop and the final assembly workshop. The outside of the welding robot should be protected by a protective cover made of industrial aluminum profiles. This protective cover is generally composed of aluminum profiles and acrylic plates, aluminum plates, or organic glass plates to prevent Sparks splashed into the human eyes; the final assembly robot should be surrounded by industrial aluminum profile safety fences. This fence is generally composed of mesh sheets and is also used to divide the safety area. In the assembly workshop, an assembly line is also used to assemble the parts and the shell. To save space, a hoist is also used. The hoist is also surrounded by industrial aluminum profile safety fences to prevent the shell or parts from being scattered and injured during work. personnel.

The assembly line of the food production workshop is also used a lot, usually, there are belt line assembly lines and a roller assembly line. Equipped with aluminum profile bar racks, the produced products can be quickly transferred to the next link, which not only ensures food hygiene but also improves production efficiency.

The requirements for aluminum profiles used in chemical raw material production lines are relatively high, and they must have a certain bearing capacity, corrosion resistance, and high-temperature resistance. Generally, rollers and chain plate lines are used; the material trucks used must also have a certain bearing capacity. Because the chemical raw materials are generally heavy and corrosive, the use of industrial aluminum profiles can just meet its needs, and it can also ensure that the workers are not harmed.

It is precise because industrial aluminum profiles have a certain bearing capacity, corrosion resistance and heat resistance, and bright color, so wherever there is a production line, industrial aluminum profile shelves, safety fences, protective covers, turnover vehicles, or The aluminum profile workbench, while carrying the goods, can also ensure that the items are not polluted, and can be used in other places after dismantling. It is durable and is the number one contributor to ensuring personal safety, reducing enterprise costs, and improving work efficiency.

About the extruded aluminum profile

Aluminum is a very commonly specified material for extrusion and shape profiles because of its mechanical properties, aluminium is well suited for forming and forming metals from billet segments. Aluminum’s high ductility means that the metal can be easily formed into a variety of cross-sections without expending a lot of energy in the machining or forming process, and aluminum’s melting point is also typically about half that of ordinary steel. Both of these facts mean that the extruded aluminum profile process has relatively low energy consumption, which reduces tooling and manufacturing costs. Finally, aluminum also has a high strength-to-weight ratio, making it an excellent choice for industrial applications.

Type: Various complex extruded aluminum profiles can be created in different thicknesses. These configuration parameters can have various complex interstitial associations that are required for end-use applications. To facilitate a variety of automation applications, and to meet any performance weight requirement, a variety of internal voids are available. The most common type of aluminum profile is the hollow beam profile, which is just a variation of the square profile.

Surface Type: As a by-product of the extrusion process, small, barely visible lines sometimes appear on the surface of the profile. This is the result of the helper tool forming when extruding, other finishes can be specified to remove these lines. To improve the surface finish of the profile section, some minor surface treatment operations, such as face milling after the main extrusion process, can be carried out. These machining operations can be specified to improve the geometry of the surface to improve the part profile by reducing the overall surface roughness of the extruded profile. These treatments are often specified in applications where precise positioning of parts is required or where mating surfaces must be tightly controlled. As a by-product of the extrusion process, secondary surface preparation operations are sometimes present on the profile surface. Aluminum is a very commonly specified material for foundations and shape profiles because of its ability to specify machining operations,

Purpose: Aluminum profiles are most commonly used in industrial automation applications such as process lines and automated motion applications throughout the manufacturing industry. They are strong and lightweight so that they can be easily handled by humans and can be built into various configurations as required by automated structures. Outside of traditional automation applications, structural-grade aluminum profiles are even specified as part of the weight reduction. In this sense, they are increasingly being used as frames for other end-use consumer products, such as automotive and LED construction projects. With the development of more advanced aluminum alloys and surface coating technologies, its use is expanding into these new areas.

What is the process of aluminum extrusion molding?

You may be unfamiliar with the concept of aluminum extrusion. In simple terms, industrial aluminum profiles are materials that are extruded from aluminum through an extruder according to a die. Whether it is European standard aluminum profiles, national standard aluminum profiles, or custom-made profiles, they are all made by aluminum extrusion. To better introduce extruded aluminum profiles, let’s take a look at aluminum extrusion. Compression molding process?

·Select high-quality raw materials: aluminum rods are made of aluminum ingots by melting and casting, which are called industrial aluminum profile raw materials; and raw materials will directly affect the performance of industrial aluminum profiles.

·Temperature-controlled heating of aluminum rods: Too high or too low temperature will directly affect the hardness of the final product, so the temperature must be strictly controlled during heating and cooling.

·Design profile molds: The molds are designed with high-precision specifications according to requirements, and are used to extrude profile products of required specifications and cross-sections.

·Extrusion of industrial aluminum profiles: At present, the standard extrusion press used for 6063-T5 industrial aluminum profiles is 1300 tons to 1600 tons, which can meet the normal production of 6063-T5 series of industrial aluminum profiles.

·Profile straightening correction: There will be a certain deviation after the extrusion of industrial aluminum profiles. After forming, a straightening machine should be used for straightening correction.

·Artificial aging: Generally speaking, the aluminum profiles produced by extrusion must be aged to improve their strength.

Extruded aluminum profiles are widely used, and high-quality raw materials are selected: aluminum rods are made by melting and casting aluminum ingots, which are called industrial aluminum profile raw materials, and raw materials will directly affect the performance of industrial aluminum profiles.

What factors should be considered when choosing industrial aluminum profiles?

Faced with a variety of industrial aluminum profiles, it is difficult for users to choose the length of time; today, I will introduce some factors to be considered when choosing industrial aluminum profiles. ; We should focus on the following points when choosing industrial aluminum profiles:

Hardness: Hardness is of course the first issue for users to consider. Of course, they are also extremely concerned about whether the hardness of aluminum profiles can meet the applicable standards. The first choice of hardness is directly related to the chemical composition added, and there is a certain Influence, in terms of the highest hardness that can be achieved, the hardness of 7 series, 6 series, 4 series, 2 series, 5 series, 3 series, and 1 series materials decrease in turn.

Strength: Strength is an important factor to be considered in product production. When the aluminum alloy is used as a component, it is necessary to select a suitable alloy according to the pressure it can withstand. The strength of pure aluminum is the lowest, and the strength of the 2-series and 7-series heat-treated alloys is the highest, and the hardness and strength have a certain linear relationship.

Corrosion resistance: Corrosion resistance includes chemical corrosion, stress corrosion resistance, and other properties. Generally speaking, 1 series pure aluminum has the best corrosion resistance, 5 series has good corrosion resistance, followed by 3 series and 6 series, 2 series and 7 series have relatively poor corrosion resistance; it should be noted that the corrosion resistance The principle of selection of properties depends on the occasion of its use. In the corrosive environment of high-strength alloys, various anti-corrosion composite materials must be used. In this way, the product can be effectively prevented from being corroded. In general use, the 5 series and the 3 series are used more. It is not necessary to choose the best 1-series pure aluminum material. It is also necessary to consider the cost. Generally speaking, choose the appropriate one. Aluminum material can be used.

Machinability: Machinability includes formability and cutting performance. Considering the formability and state, after selecting the corresponding aluminum alloy grade, it is also necessary to consider the strength range of various states. Generally speaking, aluminum with high-strength material is not easy to be formed, and the formability of the annealed material is the best after bending, stretching, deep drawing, and other forming processes of the aluminum material, while the formability of the heat-treated material is the worst. The machinability of aluminum alloy is poor, and the machinability is better for molds and mechanical parts.

Weldability: Most aluminum alloys have good weldability, and the representative ones are some aluminum alloys of the 5 series, which have excellent weldability. Relatively speaking, the weldability of the 2 series and 7 series is poor.

Decorative properties: When users buy industrial aluminum profiles, their decorative properties are also very fancy. Generally speaking, when aluminum materials are used in certain decorations or special occasions, they need to undergo anodized surface treatment and coating processing. and other processes and materials with better corrosion resistance have excellent anodizing performance, surface treatment performance, and coating performance.