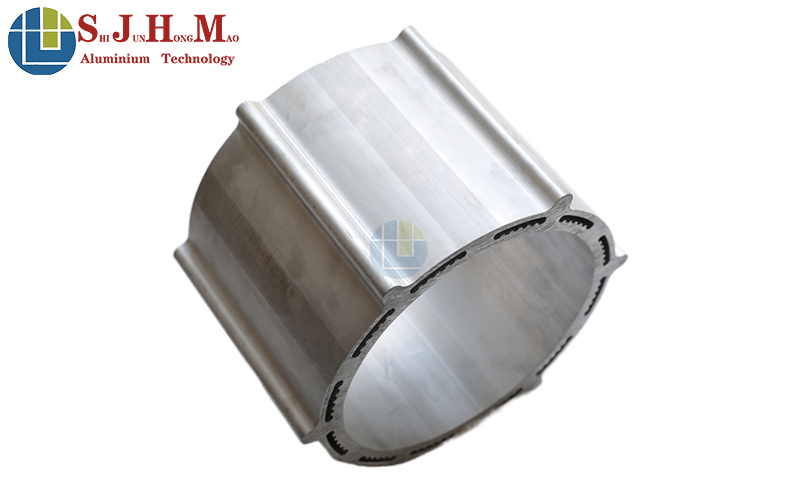

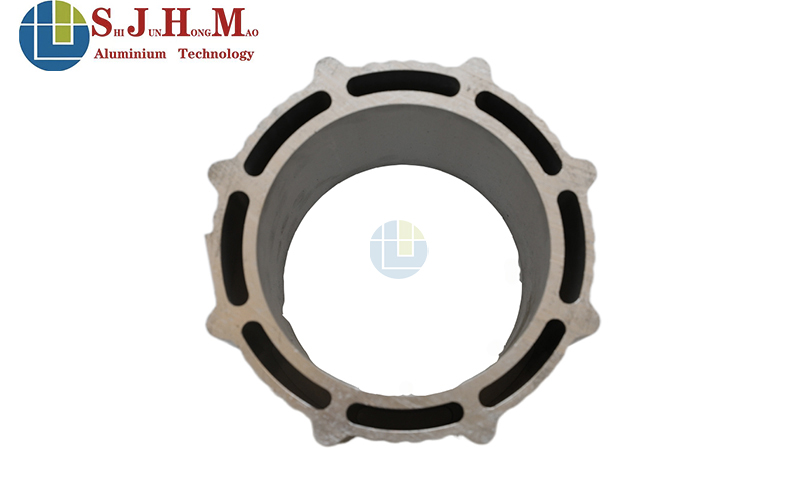

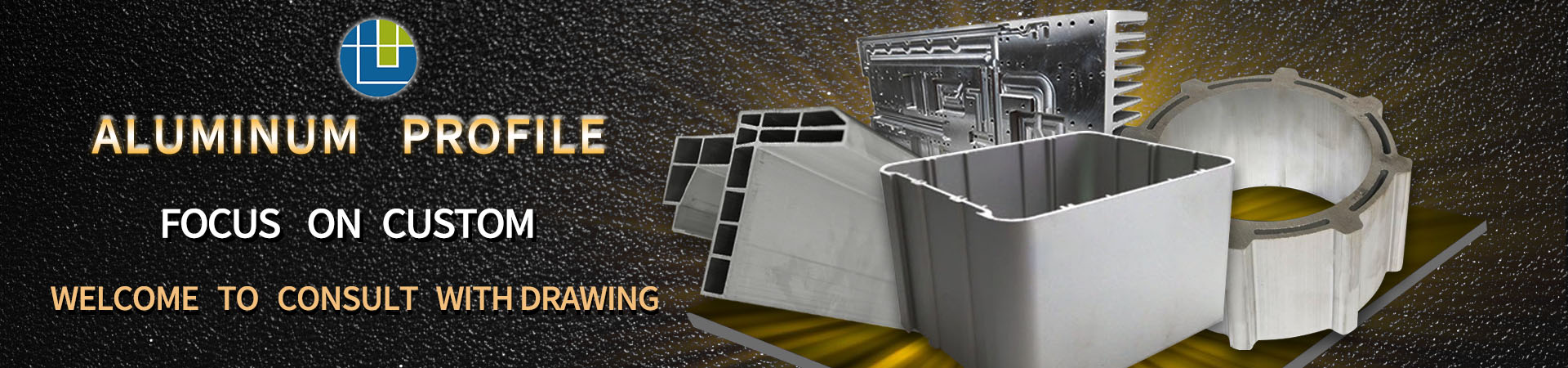

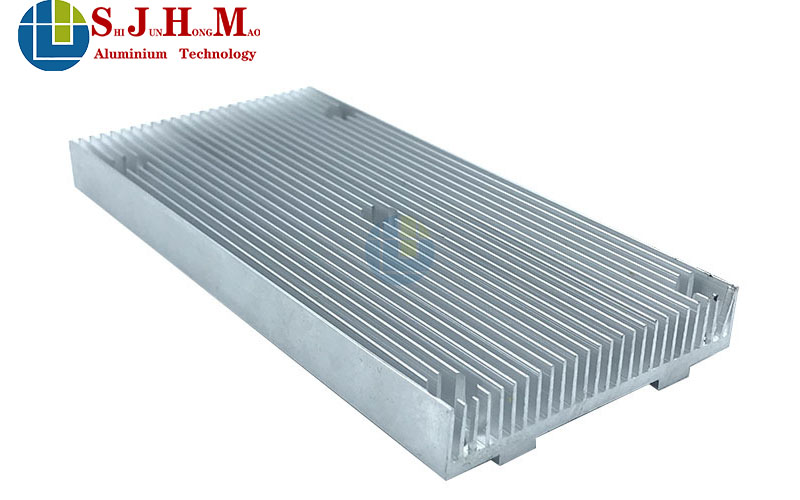

Custom Extruded Heatsink Aluminum Profile For Power Inverter

- Material: 6063、6061

- Thickness: Customizable

- Size: Customizable

- Length: Customizable

- Production process: Extrusion process

- Surface treatment: Customizable

- Packaging: Customizable

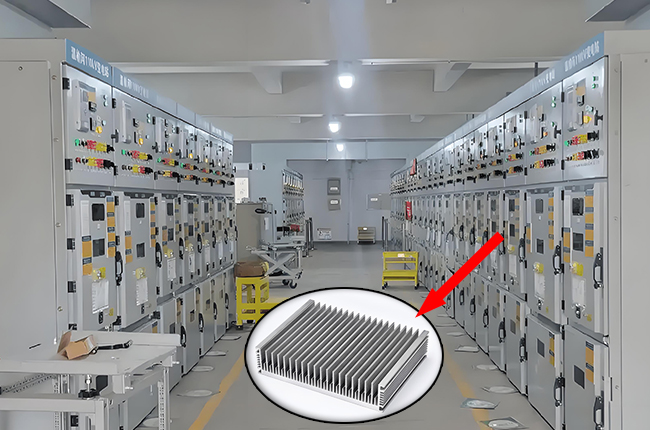

- Application: Solar power generation photovoltaic panels, electric vehicle charging stations, wind farms, communication equipment, home lighting power supplies, photovoltaic power stations