How Much Do You Know About Aluminum Enclosures?

- By:sjhmalu

- Date:19-09-2022

Aluminum alloy is a non-ferrous metal structural material widely used in industry. It is widely used in aviation, automobile, machinery manufacturing, shipbuilding, and chemical industry, especially as the enclosure. The enclosure made of aluminum alloy has incomparable advantages compared with enclosures made of other materials.

Why are aluminum alloy enclosures so popular?

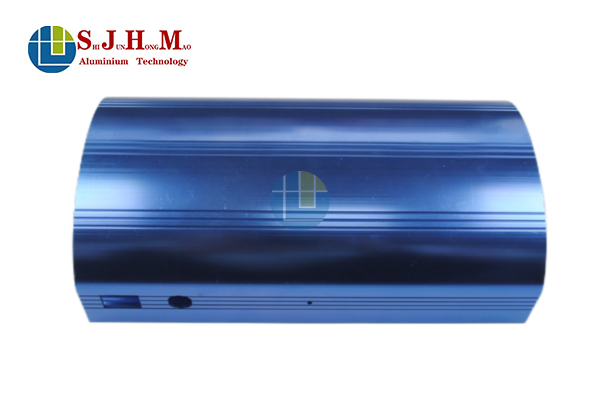

The aluminum alloy enclosure is more high-end and atmospheric than the plastic enclosure, with a metallic texture, lightweight, and strong plasticity. Another great advantage is that it is easy to dissipate heat. Also, the surface of the aluminum alloy enclosure is highly reflective. Radiant energy, visible light, radiant heat, and electrical waves are all effectively reflected by aluminum, while anodized and dark anodized surfaces can be reflective or absorptive, polished aluminum over a wide range of wavelengths With excellent reflectivity, it has various decorative uses and uses with reflective functionality.

From the past to the future, aluminum alloy enclosures have always been in a state of continuous development. Especially with the speed of technological product updates and iteration and the higher and higher requirements for products, the development of aluminum alloy enclosures has achieved significant progress. achievements and become an emerging industry. For example, today’s electronic products have abandoned the cheap plastic enclosures of the past and adopted the more beautiful aluminum enclosures. Aluminum alloy enclosure is a relatively common material in social production. It has a wide range of uses in various industries. Its excellent performance and many advantages are very popular in the majority of industries. In the future, the development prospect of aluminum alloy enclosures will be better.

Nowadays, the application of aluminum alloy enclosures is more and more extensive. Many electronic product enclosures on the market choose aluminum alloy enclosures as materials for production. Aluminum profile products are widely loved by customers. So do you know what are the characteristics of aluminum alloy enclosures? Why does the market like to use aluminum alloy enclosures? Today I will take you to find out.

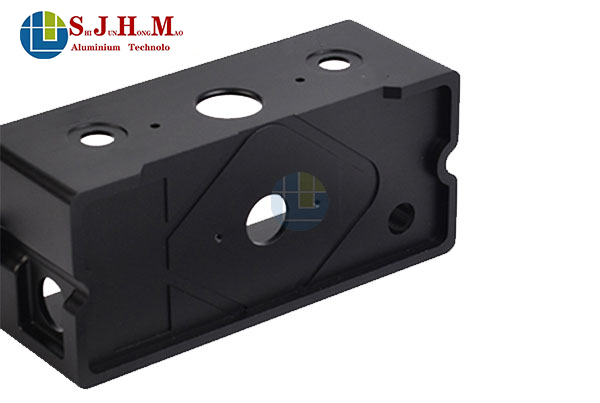

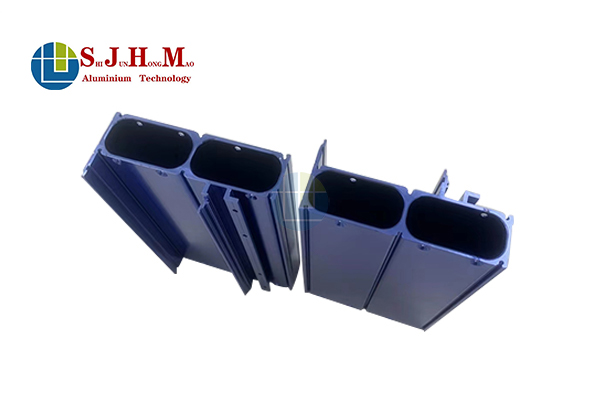

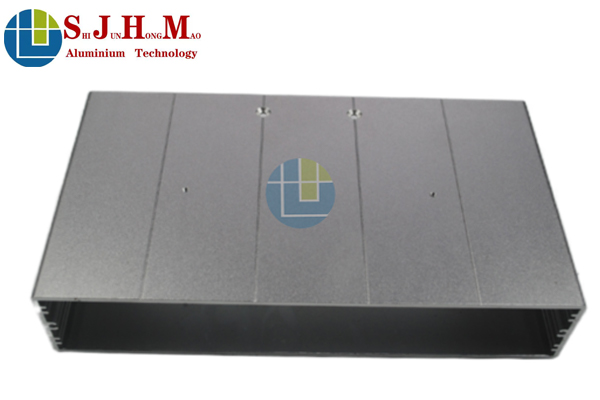

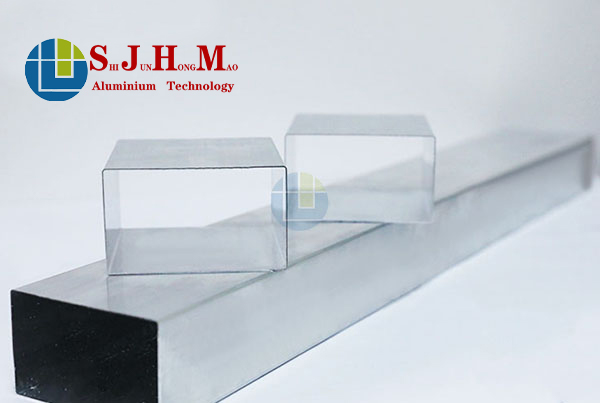

First of all, we need to know that the aluminum profile enclosure is produced by extrusion. The aluminum profile is obtained by metal stamping and surface treatment. It has high flexibility and can be arbitrarily cut in length. The board can be inserted directly, with no need to fix it again, the convenience is unmatched by other types of enclosures, and it has the characteristics of waterproof and corrosion resistance, which is very suitable for use in the wild and harsh environments; the aluminum alloy enclosure is made of aluminum alloy Various enclosures made of materials are widely used in the electronics industry because of their convenient processing, high flexibility and high grade, which can increase the added value of products and are widely used in the electronics industry, generally including aluminum profile enclosures and aluminum die-casting enclosures.

What are the characteristics of the aluminum alloy enclosure?

1. The density of the enclosure is very small, and the container is easy to manufacture and can be used as a mobile phone enclosure and a power bank enclosure. And don’t wear and be corrosion-resistant. The surface of the aluminum profile enclosure is easy to form, and a layer of dense aluminum oxide film prevents oxidation.

2. High strength, high strength of aluminum and aluminum alloys. After a certain degree of cold working, the strength of the matrix can be strengthened, and some brands of aluminum alloys can also be strengthened by heat treatment.

3. The density of aluminum and aluminum alloys is close to 2.7g/, which is about 1/3 of iron or copper.

4. The aluminum profile enclosure has no smell and can meet the standard. The color of the aluminum profile enclosure is relatively high, and it is easy to color. The opening performance of the easy-open lid made of aluminum is better than that of the tinplate easy-open lid. And with aluminum enclosure

The packaging made of this product can have excellent light and heat reflection performance and conduction performance and can improve the effect of heat sterilization and low-temperature treatment of canned food, which is relatively safe.

5. The aluminum profile enclosure is used as a packaging box, which depends on its exquisite appearance and good plasticity. Moreover, it is completely airtight and opaque in the manufacture of the aluminum film and can refrigerate food at low temperatures. Aluminum foil can also improve the aluminum-plastic composite film. The aluminum profile enclosure can be recycled twice, which is environmentally friendly and saves resources.

What are the advantages of using aluminum alloy enclosures?

At present, the enclosure material of many electronic products is mainly aluminum alloy, and the aluminum alloy enclosure has become one of the mainstream products in the electronic industry. This is mainly determined by the unique advantages of the aluminum alloy enclosure, so what is the aluminum alloy enclosure? What about the advantage?

Simple installation: Because the density of aluminum profiles is small and can be processed into various shapes, it is more convenient to assemble. Even if the surface is damaged, it can be quickly repaired, and cumbersome processing procedures are no longer required.

High safety factor: Because of its high strength and rigidity, the aluminum alloy enclosure can accept enough pressure, bending force, tension, and impact force even in an enclosure of relatively thin thickness, and still can show a good safety factor, which can effectively Protection of internal electronic components, product use is guaranteed.

Long service life: The aluminum alloy enclosure has relatively low requirements for the use environment. Even in a relatively poor environment, it is also good protection for the use of electronic products, with strong corrosion resistance, and the use of aluminum alloy enclosure can reduce damage; aluminum alloy The enclosure produced is hard, can be cold worked to strengthen its hardness, and has excellent electrical and thermal conductivity, which is more in line with the needs of the current market than enclosures made of other materials.

Excellent performance: The enclosure of the aluminum profile can produce a thick and solid oxide film, which can be used in electronic components for a long time without corrosion due to environmental elements, and has strong durability.

Low cost: Due to its excellent performance, the aluminum alloy enclosure has a much longer service life than other materials, and the product has a long service life, which greatly reduces the cost of use.

Strong application environment: the aluminum alloy enclosure has high flexibility, good anti-leakage performance, a depth that can be arbitrarily cut according to needs, and strong waterproofness. It can also be used in the field and in places with poor environments, with strong adaptability.

Easy to handle: The aluminum alloy enclosure is easy to process. After adding certain alloying elements, a forged aluminum profile with relatively excellent forging function or a deformed aluminum profile with better processing plasticity can be obtained. The basic strength can be strengthened, and after certain heat treatment, the service life of the product can be extended, and the processing procedure is simple.

High recovery rate: The aluminum alloy enclosure can be replaced at any time if it is damaged during use, and the replaced product can be recycled, which protects resources and the environment at the same time.

What are the advantages of custom aluminum profile enclosure production?

Our company’s manufacturing level and corresponding process modes are becoming more and more diverse, and the application of different aluminum alloy enclosure aluminum profiles has also brought a better foundation for our customers’ product applications. The company’s customers are now the basis for high-quality aluminum application and efficient processing. Customers can also enjoy more high-end processing technology with the help of the many benefits brought by this customized aluminum alloy enclosure profile. According to the analysis of this customized aluminum alloy enclosure profile, The benefits are rough as follows:

It can improve the level of subsequent personalized processing; it goes without saying that better modeling ability and more excellent overall processing effect can improve the quality of subsequent designs, and the improvement of our company’s relatively prominent aluminum profile enclosure customization technology is one of the Its overall modeling ability has been better realized, and the innovation and creativity of the product have been greatly improved so that it has better characteristics. With the help of this aluminum profile customization process, personalized processing can be realized. The manufacturing process of our products has been better realized, and it can also be used as a basis to enrich and follow up personalized design processes so that this aluminum profile customization technology can be used for our subsequent product development and various process applications. brings a better foundation;

All in all, this kind of aluminum profile customization process has made our company’s aluminum profile product research and development effects achieve more diverse changes, and the integrity and creativity of its structural modeling have brought outstanding application effects, so customers must understand The customized process and actual presentation effect of this aluminum profile, select reliable products to maintain their own creativity and application needs.

About the anodized aluminum alloy enclosure

In today’s market, aluminum alloy enclosures are widely used in both life and industrial products. Aluminum alloy enclosure products can be seen everywhere on the street, and the popularity of aluminum alloy enclosures is increasing day by day; aluminum alloy enclosures can adapt to a certain environment or achieve certain functions, and enterprises will also choose different processes to treat the surface of the aluminum enclosure, such as Anodizing, electroplating, spraying, micro-arc oxidation, etc. Among them, the anodizing process is a widely used process in the processing of aluminum alloy enclosures. It can form an anodized mold with a certain thickness, strength, and aesthetics on the surface of the aluminum alloy enclosure. What are the characteristics of adding anodizing process to aluminum alloy enclosure processing?

Anodizing refers to the process in which aluminum and its alloys form an oxide film on aluminum products (anode) under the action of an applied current under the corresponding electrolyte and specific process conditions. Unless otherwise stated, anodizing generally refers to sulfuric acid anodizing. In order to overcome the defects of surface hardness and wear resistance of aluminum alloys, expand the scope of application and prolong the service life, surface treatment technology has become an indispensable part of the use of aluminum alloys. Anodizing technology has been widely used, and anodized aluminum enclosures have also been widely used.

After the aluminum alloy enclosure is anodized, a layer of anti-corrosion, wear-resistant, and beautiful oxide film will be formed on the surface. The characteristics of the oxide film also establish the position of anodization in the surface treatment process. The aluminum alloy housing is anodized with a protective “coating”. Since the chemical properties of the anodized film are very stable in the natural environment, it can provide anti-corrosion protection for the aluminum alloy enclosure. At the same time, the anodized film has high hardness, low roughness, and a smooth surface, which greatly improves the wear resistance of the aluminum enclosure. If various organic and inorganic dyes are added during the anodizing process, the anodized film is colored, which gives the anodized aluminum enclosure a beautiful appearance.

The anodizing process is very beneficial to the aluminum alloy enclosure, but when doing this process, some directional silver-black streamline stripes are often formed on the surface of the aluminum alloy enclosure. These streaks are caused by certain defects and impurities on the surface of the aluminum alloy die casting during the anodizing process. The current of anodizing is unevenly distributed on the surface of the product. In some places the current is small and in some places the current is large. The flow rate of the electrolyte will be slowed down at the depression and the flow rate at the tip will be increased. The effect of anodizing is uneven, and black stripes appear on the surface of the aluminum alloy enclosure, so be very careful when polishing the aluminum alloy enclosure.

What are the characteristics of the new energy battery aluminum alloy enclosure aluminum material?

New energy battery enclosure aluminum-aluminum material has become the emerging darling of the automotive industry in recent years due to its lighter weight and performance; chassis and other systems are widely used; in addition, with the outbreak of the new energy vehicle market, all-aluminum body, aluminum alloy battery packs and other aspects have also ushered in a climax of development and application.

Lightweight and high safety make aluminum alloy battery pack enclosures the mainstream of power battery enclosures. The power battery enclosure is made of aluminum material, which has the advantages of easy processing and forming, good high-temperature corrosion resistance, good heat transfer, and electrical conductivity. Therefore, the battery enclosure using aluminum alloy under the same capacity is thinner and lighter in relative weight than the steel enclosure. In addition, once the battery explodes, the aluminum enclosure of the lithium battery is weaker than the steel enclosure, and the harm caused by the aluminum enclosure power battery is relatively lower. So what are the characteristics of the aluminum material of the new energy battery enclosure that make it so popular? Today I will take you to find out.

1. The battery aluminum enclosure has a high specific strength, specific modulus, fracture toughness, fatigue strength, and corrosion resistance stability. Because aluminum alloy material has the characteristics of low density, non-magnetic, stable alloy phase at low temperature, small specific resistance in a magnetic field, good air tightness, and fast attenuation of induced radiation energy, it is widely used in aviation, aerospace, high-speed trains, machinery manufacturing, It has been widely used in ships, automobiles and chemical industries.

2. The surface treatment of the battery aluminum enclosure is mainly electrostatic spraying, and its color is also very rich, and colors are generally beige, dark gray, black, military green, etc.

3. The aluminum battery enclosure has the advantages of aluminum alloy, so it is also light and durable when it is formed.

4. The plasticity of the battery aluminum enclosure is stronger, the productivity is relatively better than other profiles, and it also has good castability, so it has a good advantage for production.

5. The battery aluminum enclosure will be treated by two processes of hot and cold so that the battery aluminum enclosure made in this way will have strong corrosion resistance. Therefore, the battery safety of the aluminum enclosure is better.

6. This enclosure also has good ductility and can be made of light alloys with many metal elements, and the material is of high quality. Its chemical properties are stable, non-magnetic, and can be recycled and reused. It is a virtuous and recyclable metal material.

Aluminum alloy battery enclosure is an important supporting industry for the new energy vehicle industry. Under the level of established product structure and technology, there is a fixed ratio of 1:1 between aluminum alloy battery enclosures and new energy vehicles. Therefore, the market demand, industrial scale, and development space of aluminum alloy battery enclosures are closely related to the downstream, and the development prospects are broad.

Why do mobile power supplies use aluminum alloy enclosure profiles?

At present, most of the enclosures used for mobile power products on the market are divided into two categories: metal materials and non-metal materials. The material of the enclosure determines the tactile feel and heat dissipation performance, which can improve the overall competitiveness of the product. Although the net weight of the plastic material enclosure is lighter and more convenient to carry, the aluminum profile enclosure is taller and higher-grade than the plastic enclosure has a metallic luster, and is light and ductile.

The reasons why the mobile power supply chooses the aluminum profile enclosure are as follows:

1. High strength: Aluminum and aluminum alloys have high strength. After a certain degree of cold working, the strength of the matrix can be strengthened, and some aluminum alloys can also be strengthened by heat treatment.

2. Low density: the density of aluminum and aluminum alloys is about 1/3 of that of iron or copper.

3. The aluminum profile enclosure has no peculiar smell and meets national health standards. The aluminum profile enclosure has a bright color and is easy to color. The opening performance of the aluminum easy-open lid is better than that of tin plating, and the packaging made of the aluminum profile enclosure has excellent light and heat. The reflective performance and conductivity can improve the effect of heat sterilization and low-temperature processing of food cans, and it is relatively safe.

4. The density of the aluminum alloy enclosure is very small, which can be used as the enclosure of mobile phones and mobile power sources, is wear-resistant and corrosion-resistant, and the surface is easy to form.

5. The box is made of an aluminum profile enclosure, with its exquisite appearance, it has excellent plasticity, in addition, the aluminum film is completely airtight and opaque, the food can be refrigerated at low temperature, and the aluminum foil can also increase the strength of the aluminum-plastic composite film. The secondary recycling of the aluminum profile enclosure is both environmentally friendly and resource-saving.

About the large extruded aluminum enclosure

About the large extruded aluminum enclosure

What is enclosure extrusion? When you need to buy a custom aluminum enclosure, you may consider whether to design and make the enclosure through an extrusion die. What is the extrusion aluminum process?

Extrusion is one of the processing methods for converting aluminum alloys into shapes with defined cross-sectional profiles for a variety of applications. Taking advantage of the physical properties of aluminum, aluminum profiles can be used in construction, ships, and especially in the manufacture of electronic enclosures. What is extruded aluminum used for?

As mentioned above, thanks to the stable properties of aluminum, it is suitable for various fields. Examples include architectural wood products, the solar renewable energy industry, bridge decks, and especially electronic enclosures.

The benefits of aluminum electronic enclosures

Compared to other manufacturing techniques, extruded aluminum offers many distinct advantages, including corrosion resistance, high strength-to-weight ratio, high strength, and more. But what do these benefits mean for extruded aluminum boxes?

①Excellent performance in various environments

Extruded aluminum project boxes perform well in all different environmental conditions. Because aluminum is UV stabilized, the box will stay solid in sunlight and protect some PCB components from harsh sunlight.

② Effectively prevent interference

The one-piece aluminum enclosure strives to prevent radio frequency interference (RFI) or electromagnetic interference (EMI). Additionally, aluminum has strong signal absorption capabilities, so it can block signals from sensitive internal PCB components.

③Support custom design

High ductility, high strength, and good stability all allow enclosure manufacturers to provide custom aluminum enclosure services. It is easily formed, extruded, and machined into complex shapes. This means that you can list to your manufacturer the specific construction of an aluminum enclosure or a complete sketch design to produce the ideal and perfect electronic enclosure.

④Excellent durability

The combination of aluminum and extrusion technology ensures that the aluminum enclosure is more damage-resistant and thicker than regular rolled aluminum.