What do you need to know about aluminum alloy profile radiators?

- By:sjhmalu

- Date:22-11-2022

About aluminum radiator

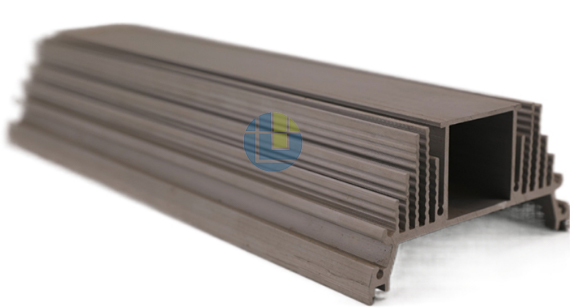

In today’s era of rapid development, society is constantly progressing, and new things derived from new technologies have entered our lives, and it has changed our way of life invisibly. Today we are going to show you aluminum radiators. This product, the radiator is used in all corners of life, and everything that can be seen is inseparable from it, such as automobiles, electronic appliances, LED lights, mechanical equipment, inverters, computer cases, CPUs, and other products that have radiators. , it can be seen that the radiator has a wide range of applications.

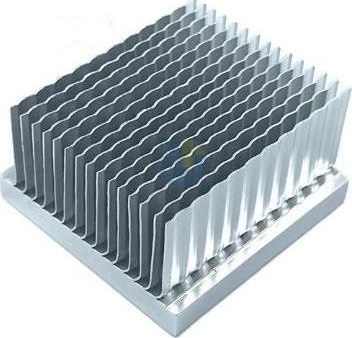

The extruded aluminum radiators can be made many and thin because of their fins, and the area of the radiator has been widened to the greatest extent. , and the cooling fins will form air convection to diffuse heat during operation, and the heat dissipation effect is very good; Put the heat out nicely.

The aluminum profile radiator is made of aluminum alloy material. The aluminum alloy material has high thermal conductivity, large heat dissipation coefficient, fast speed, and high metal thermal strength. In addition, the surface of the aluminum profile can be processed by anodizing to generate a layer of dense oxidation. The film can effectively prevent the corrosion of products such as ultraviolet rays, has excellent oxidation corrosion resistance, longer product life, is not easy to damage, and high safety factor.

Why choose aluminum as the raw material for an aluminum radiator?

When you have heard of and purchased aluminum radiators, it is not difficult to find that radiators are often combined with aluminum to become products, and in the radiator industry, people are also used to calling them aluminum radiators. Why are radiators mostly made of aluminum as raw materials? What are the advantages of aluminum, and what are the advantages of aluminum profile manufacturers using aluminum as the raw material for radiators to produce radiators?

·Lightweight: Aluminum is a light metal with a density of only 2.7g/cm³, which is about one-third of the density of copper and iron. When used to produce radiator panels and housings, aluminum profiles of the same volume are compared with other materials. It is lighter in weight, and using it as a raw material for electronic products such as radiators is very in line with the current lightweight development environment. Not only that, aluminum radiators are very easy to install, easy to handle, and save labor costs and time costs.

·Corrosion resistance: The working environment and application environment of general radiators are relatively complex. At this time, there must be strict requirements for the selection of raw materials for the production of radiators, so as to meet the production standards. The corrosion resistance strength requirements of aluminum profiles are relatively high. And the surface of the aluminum material will form a dense oxide film after oxidation treatment, which is used to protect the aluminum matrix from being eroded and damaged. Not only that, the corrosion resistance of the aluminum profile after surface treatment becomes stronger. If the aluminum profile is the raw material of the radiator, there is no need to worry about the aesthetics and heat dissipation problems caused by corrosion in the later stage of the product, and the life of the aluminum profile radiator can also be guaranteed.

·The heat dissipation performance of the aluminum profile is excellent: the heat dissipation performance of the radiator is about the heat dissipation performance, which is an extremely important part of the radiator. The heat dissipation performance requirements of the raw materials used in the radiator must be high. It can be seen that the thermal conductivity of aluminum is 204/w ( m·k), although pure aluminum has low hardness and is easily deformed by heat, after processing pure aluminum into the aluminum alloy, there is no need to worry about heat deformation, on the contrary, it also has excellent heat dissipation performance.

·Non-magnetic: As the raw material of some radiator shells, especially the radiator shells that need to be used in electronic products must ensure that there is no magnetism, this is to prevent interference to the transmission of signals, and does not contain iron, cobalt, nickel, etc. The aluminum alloy of the metal element is not magnetic, so the radiator shell made of aluminum will not affect the operation of electronic products, and it can be used with confidence.

What are the advantages of aluminum profile manufacturers using aluminum as the raw material for radiators to produce radiators?

1. Lightweight: Aluminum is a light metal with a density of only 2.7g/cm³, which is about one-third of the density of copper and iron. When used to produce radiator panels and housings, aluminum profiles of the same volume are compared with other materials. It is lighter in weight, and using it as a raw material for electronic products such as radiators is very in line with the current lightweight development environment. Not only that, aluminum radiators are very easy to install, easy to handle, and save labor costs and time costs.

2. Corrosion resistance: The working environment and application environment of general radiators are relatively complex. At this time, there must be strict requirements for the selection of raw materials for the production of radiators, so as to meet the production standards. The corrosion resistance strength requirements of aluminum profiles are relatively high. And the surface of the aluminum material will form a dense oxide film after oxidation treatment, which is used to protect the aluminum matrix from being eroded and damaged. Not only that, the corrosion resistance of the aluminum profile after surface treatment becomes stronger. If the aluminum profile is the raw material of the radiator, there is no need to worry about the aesthetics and heat dissipation problems caused by corrosion in the later stage of the product, and the life of the aluminum profile radiator can also be guaranteed.

3. The heat dissipation performance of the aluminum profile is excellent: the heat dissipation performance of the radiator is about the heat dissipation performance, which is an extremely important part of the radiator. The heat dissipation performance requirements of the raw materials used in the radiator must be high. It can be seen that the thermal conductivity of aluminum is 204/w ( m·k), although pure aluminum has low hardness and is easily deformed by heat, after processing pure aluminum into the aluminum alloy, there is no need to worry about heat deformation, on the contrary, it also has excellent heat dissipation performance.

4. Non-magnetic: As the raw material of some radiator shells, especially the radiator shells that need to be used in electronic products must ensure that there is no magnetism, this is to prevent interference to the transmission of signals, and does not contain iron, cobalt, nickel, etc. The aluminum alloy of the metal element is not magnetic, so the radiator shell made of aluminum will not affect the operation of electronic products, and it can be used with confidence.

What are the advantages of an aluminum alloy electronic radiator?

In the current electronic market, electronic products are gradually moving towards miniaturization, and with the development of precision, the application of aluminum alloy electronic heat dissipation is becoming more and more extensive and frequent. What are the advantages of an aluminum alloy electronic heat sink?

With the development of science and technology, the scale of the aluminum profile industry has expanded, and batches of radiators have been continuously produced. The combination of new aluminum alloy materials of different varieties and uses with the radiator has created a variety of aluminum profile radiators. Energy saving, green environmental protection, and high-efficiency radiators are developing in the direction of development; although aluminum alloy radiators are slightly inferior to copper and other materials in terms of heat dissipation performance, their heat dissipation coefficients can already meet the requirements of most electronic products, not only that, Another reason for using aluminum alloy materials is that they have advantages in terms of weight, processing, beautiful appearance and price so that aluminum alloy radiators are now widely used and become the main force of radiators.

The high thermal conductivity of aluminum alloy is the decisive factor to maintain good heat dissipation function and an ideal medium for thermal energy conversion. It is characterized by less time, fast heating, and high efficiency. Lightweight and easy to process. For radiators of the same specification, the weight of aluminum alloys is much lighter than that of steel radiators.

Among various radiators, aluminum alloy radiators are relatively light, easy to carry and install, and at the same time, it has good thermal conductivity, large heat dissipation, fast heat dissipation, high metal thermal strength, novel and beautiful appearance, strong decoration. Since aluminum oxide is oxidized to generate aluminum oxide, which is the best protective film, it can avoid further oxidation, so it is not afraid of oxidation corrosion. In addition, the price is moderate, so it is very popular with users.

Aluminum alloy material has excellent thermal conductivity, which is the main factor to keep the product with a good radiator. It has fast heat dissipation, fast heat supply, high speed, and simple processing and production. Compared with steel radiators of the same specification, aluminum alloy radiators are far superior.

Among many radiators, from the perspective of production and processing, aluminum alloy is an ideal material for the production of radiators. It has advantages over other materials in terms of energy saving, material saving, decoration, price, and weight.

Do you know the production process of aluminum radiators?

Aluminum profile radiator refers to aluminum profiles with different cross-sectional shapes obtained by hot-melt extrusion of aluminum strips; I believe many users are curious about the production and forming process of aluminum profile radiators, so do you know what are the production process steps?

First of all, we must understand that the production process of aluminum profiles mainly includes casting, extrusion, and coloring (the coloring is mainly divided into oxidation, electrophoretic coating, fluorocarbon spraying, wood grain transfer, and other technologies)

Let’s take a look at the main production process of the aluminum radiator.

The first step (ingredients): Calculate the number of various alloy components added according to the required aluminum alloy grades, so as to match the appropriate raw materials.

The second step (smelting): the prepared raw materials are added to the melting furnace for melting according to the requirements of the process, and the impurity residue gas in the furnace is removed by refining treatment such as degassing and slag removal during this period.

The third step (melting and casting): The molten aluminum that has been melted and cast passes through a certain casting process condition passes through a deep well casting system, and is cooled and cast into round cast rods of various specifications.

The fourth step (extrusion): According to the section design of the profile product, a mold is manufactured, and the heated round cast rod is extruded into the desired shape in the mold by an extruder.

The fifth step (oxidation): The surface corrosion resistance of the extruded aluminum alloy profile is not strong enough. At this time, anodizing or powder spraying is required for proper surface treatment to increase the corrosion resistance, wear resistance, and corrosion resistance of the aluminum alloy. Beautiful appearance.

The oxidation process is mainly:

①Surface pretreatment: Use chemical or physical methods to clean the surface of the profile (acid washing or alkali washing) to expose the pure substrate, which is conducive to obtaining a complete and dense artificial oxide film, and can also be mechanically cleaned. This means obtaining a specular or matt (matt) surface.

②Anodizing treatment: Under certain process conditions, the surface of the pretreated profile will undergo anodization on the surface of the substrate to form a dense, porous, and strong absorbing Al2O3 film.

③ Sealing: The pores of the porous oxide film formed after anodization are sealed, so that the anti-pollution, corrosion resistance, and wear resistance of the oxide film are enhanced. The oxide film itself is colorless and transparent but using the strong adsorption of the oxide film before sealing, some metal salts are adsorbed and precipitated in the die hole, which can make the appearance of the profile show other colors other than its original color (silver white). , such as black, golden yellow, bronze, and so on.

Can aluminum profile radiators be custom processed?

Many customers will ask us if they have ready-made molds when they consult for the first time. I am very sorry to say that we are a customized manufacturer of aluminum profiles. What is customized production? It is a product for each customer. One mold only belongs to one customer and will not be delivered to other customers. In order to accurately produce the products that customers want, we believe that customized production is necessary and will continue to be implemented.

At present, terms aluminum profile radiators, in addition to some conventional radiators, electronic product radiators, LED lamp radiators, new energy electric vehicles, etc. are all within the scope of our production. aluminum racing radiator aluminum racing radiator aluminum racing radiator

What is the content of custom processing and production?

I believe that everyone is very interested in this. Let’s take a look at what we need to know about custom processing and production.

·Appearance and appearance: We produce many styles of aluminum radiators, which are mainly produced according to the customer’s drawings to confirm the specific size specifications. If the customer is not satisfied with the length of the radiator, we can cut the length according to the customer’s requirements, not only In this way, the requirements for changing the appearance of the aluminum radiator such as opening and cutting holes can be met.

·Color: Generally speaking, custom-made aluminum radiators are silver-white and black. We default to a silver-white treatment. In addition to conventional colors, other colors can be changed according to customer needs. automotive radiator suppliers automotive radiator suppliers

·Batch customization of fine aluminum profile processing, which can be processed according to customer drawings, aluminum profile design, etc.; factory direct sales, can be customized by drawing and mold opening, after the surface of the processed aluminum radiator is anodized, the corrosion resistance of aluminum The durability, wear resistance and aesthetics are greatly improved, which can meet the needs of on-site delivery.

How much do you know about car radiators?

As we all know, the car radiator is a very critical component in auto parts, and the car radiator is composed of a water inlet chamber, a water outlet chamber, and a radiator core. The coolant flows in the radiator core, the air passes outside the radiator, and the heat The coolant becomes cold due to the heat dissipated to the air, and the cold air increases in temperature because it absorbs the heat dissipated by the coolant; the operation of the radiator is that the internal combustion engine will become very hot when it is running, due to many The fast-moving friction of the metal parts inside the engine generates a lot of heat. The engine relies on the coolant to keep these parts cool and ensure that they do not fail due to overheating; in addition to keeping cool, the coolant comes from the metal parts. The heat is transferred to the coolant, the coolant passes through the radiator, the radiator takes this heat out of the coolant and puts it into the air that the fan replaces, and the coolant circulates back to the engine to cool the components again, completing a The operation of the cycle.